Jalan House: Small details, big benefits

Last month’s visit to the Jalan House site demonstrated the rapid progress that has been made with the Passivhaus timber frame by David and the crew from Mike Whitfield Construction, with skeletal timber frame construction already up to ridge level. At the time of writing this is now almost fully sheathed in!

The main structural element of the entire shell is I-joists; in this case from Masonite. I-joists are a fantastic method of construction in Passivhaus as the narrow web reduces the amount of timber in the insulation zone and improves thermal performance.

In order to structurally connect the walls and roof of the Passivhaus timber frame together, additional strengthening is required at the eaves junction by way of plywood gusset plates. This causes one issue in particular, the forming of a small void between the plate and the flange of the I-joists. Small voids like this can drastically affect the performance of the thermal envelope and need to be carefully addressed. The most common method of insulating “closed panel” constructions is by pumping loose insulation into them, in the case of Jalan House, this will be Warmcel by one of their Approved Installers, and it is unlikely that this void would be filled adequately by this method alone.

The answer? Planning and detailing

These areas, and other small voids, need to be pre-insulated to retain the continuity of insulation at one of the thermally weaker parts of the envelope.

This is normally done with a suitably sized piece of insulation, equal, or better in performance, than the insulation being used to fill the zone surrounding it. This ensures that there is no unwanted decrease in performance here.

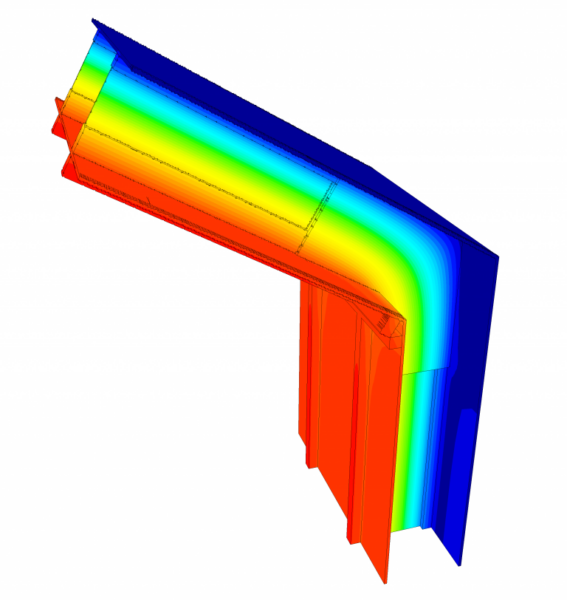

When modelled in SOLIDO, we can see this retention of performance by the smooth nature of the temperature gradient across the connection which is almost identical to that through the I-joists (the Warmcel has been removed from the model here for clarity).

In addition to their use in the external structure, I-Joists are very well suited to use in floors due to their enhanced ability to span over large areas when compared to solid timber. This though, does also require good detailing and significant planning, particularly when using long spiral-wound duct sections.

The moral of this story? Plan ahead, as there is little chance to rectify these areas easily or efficiently once a mistake has been made.