For insulation to work as intended and for floors, walls and roofs to achieve the needed thermal transmittance (U-value) gaps in the insulation need to be small. This is because air movement in the gaps results in thermal bypass which significantly undermines thermal performance. This is well recognised and is commonly expressed in insulation installation guides and product certificates. The Passivhaus standard is not explicit on gaps in insulation but it is expected that the insulation installation is carried out to a high standard and In Passivhaus gaps above 3mm are usually considered problematic and have to be foamed or otherwise filled.

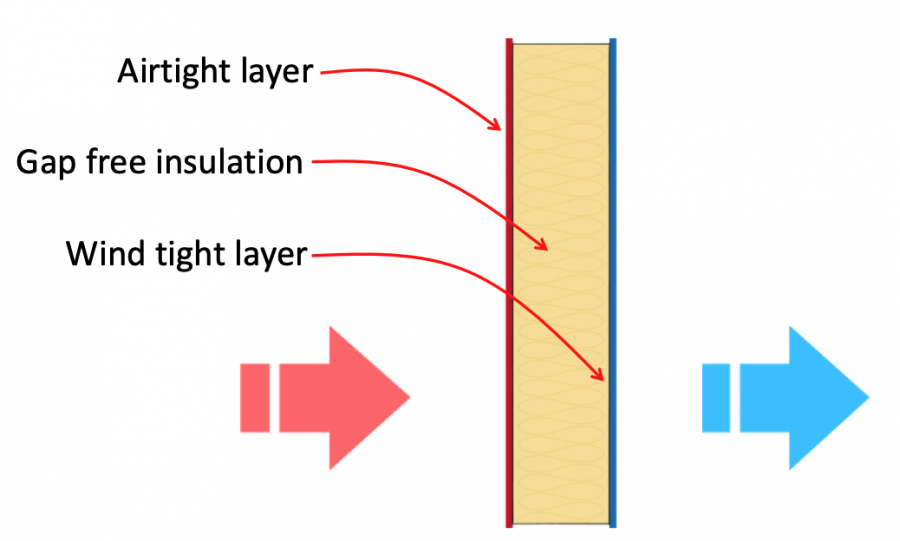

Common practice in Passivhaus buildings is to encapsulate gap-free insulation between an internal airtight layer and an external wind tight layer.

A site QA process is needed to ensure the correct installation of the insulation and demonstrate the quality of the works. Our stepwise QA process involves:

- office based design review to finalise the process and sequencing and address any risk areas

- site based benchmarking at the start of each aspect of install to establish and demonstrate the required quality level

- ongoing evidence collection

We were recently on site at Lyde Green school with main contractor BAM and groundwork contractor Certus Construction to benchmark the quality of the initial insulation works. The ground floor area is around 4600m2, so it is important to get this element of the construction right from the outset.

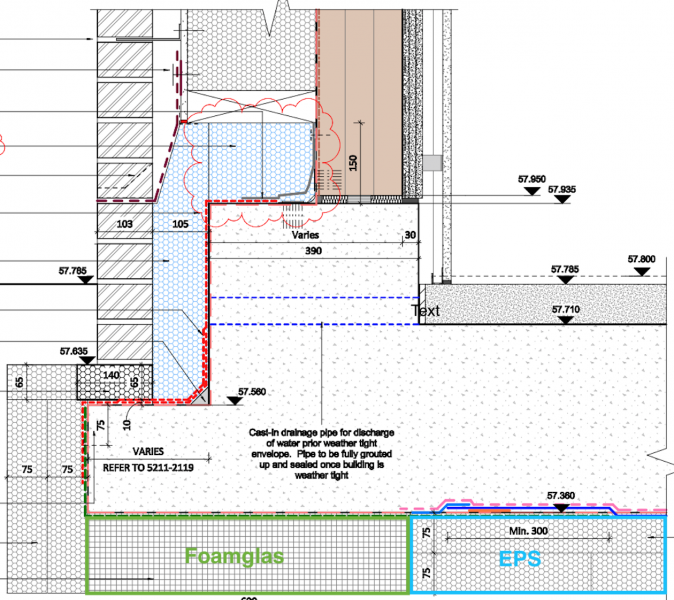

The ground floor construction as designed by Alec French Architects, is as shown below, with 150mm of continuous insulation below the concrete raft foundation. The concrete forms the airtightness layer and the oversite/ground ensure encapsulation of the insulation:

The Foamgals is structural insulation required around the whole perimeter to bear the weight of the walls, whilst the EPS is below the rest of the floor. The only deviation is the lift pit. What we love about this design is that there is no thickening of the concrete which means there are very few angle cut insulation boards, making the job on site much easier.

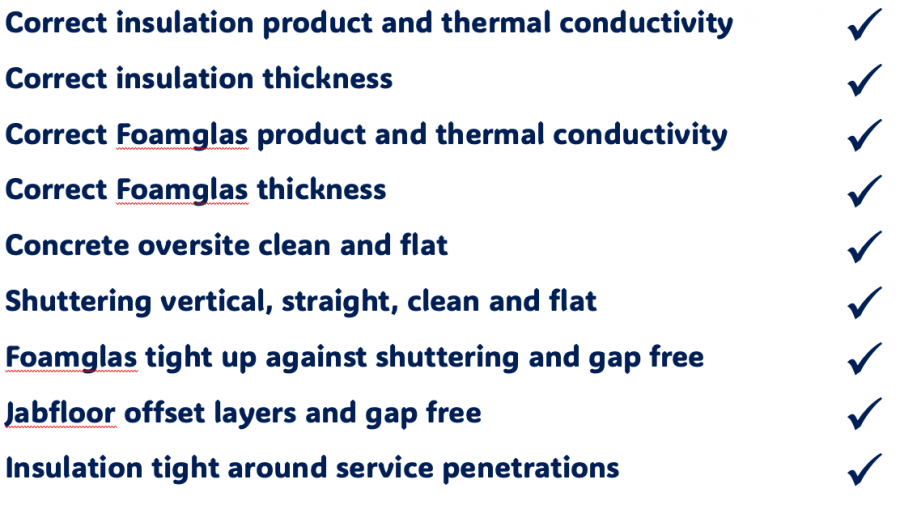

The benchmarking involved the following checks:

We were very impressed with the quality and that so far there had been no need for any foaming of gaps. Following successful benchmarking, the site team have a good understanding of what they need to do to complete this stage of works to the required standard. Evidence collection will be undertaken by the BAM Passivhaus Champion and Certis team; the insulation quality will be signed off before it is covered with the waterproofing membrane and Delta Q will be on hand for queries and trouble-shooting.

The next benchmarking visits will be for the lift pit and then when the vertical insulation is offered up against the toe of the concrete. We are envisaging that the surface will be somewhat uneven due to the membrane between the concrete and the shuttering and we will use a gap filling adhesive to fill the gap.