One of the key Passivhaus quality assurance strategies Delta Q encourages on site is setting benchmarks for construction quality where the first area of key works installed is reviewed and documented.

Delta Q were on site at our John Street project this week to undertake such a benchmark for below DPC insulation installed by the John Street site team: Higgins Construction, Amery Construction and Regents Contracting Limited.

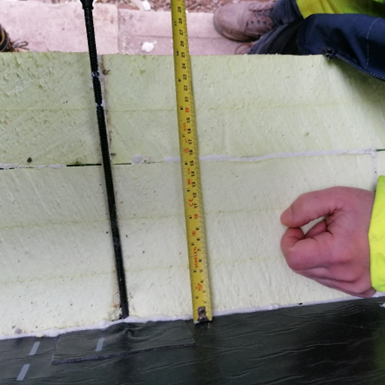

Below DPC, insulation tends to be rigid boards like XPS to withstand moisture. Concrete has tolerances and is never perfectly flat, waterproofing membranes have a thickness which can impede on the insulation zone and any damage to rigid insulation can create gaps when installed. As such ensuring there are no gaps between rigid insulation boards or between the internal structure and the insulation can be difficult and requires extra care and attention.

Given these challenges, it was great to see the quality of work by the John Street team and the care and time they had taken to install the below DPC insulation setting a very high standard for their Passivhaus benchmark as documented below.

Double sided tape was applied to the XPS boards to ensure they were fitted tight to the internal structure with no gaps:

Insulation boards were staggered in two directions ensuring the edges of the layers did not align:

Waterproofing which doubles as the airtightness layer in this zone was carefully sealed including around all low thermal conductivity ties:

Brick setting out was double checked to ensure no reduction in the insulation layer and the ties were recessed into the insulation by making a shallow cut below, ensuring they were flush before the next layer above was installed:

Passivhaus quality assurance in practice – overall a very good quality installation: